Glossary of Common Terminology - Robotics, Design, and Manufacturing

Share

There are lots of terms and acronyms used in bot design! Here is a quick reference guide to some of the most common robot design and manufacturing terms, materials, and more.

Sources: Written by Seth Schaffer, provided by Hubs.com, or inspired by this article.

General Terms

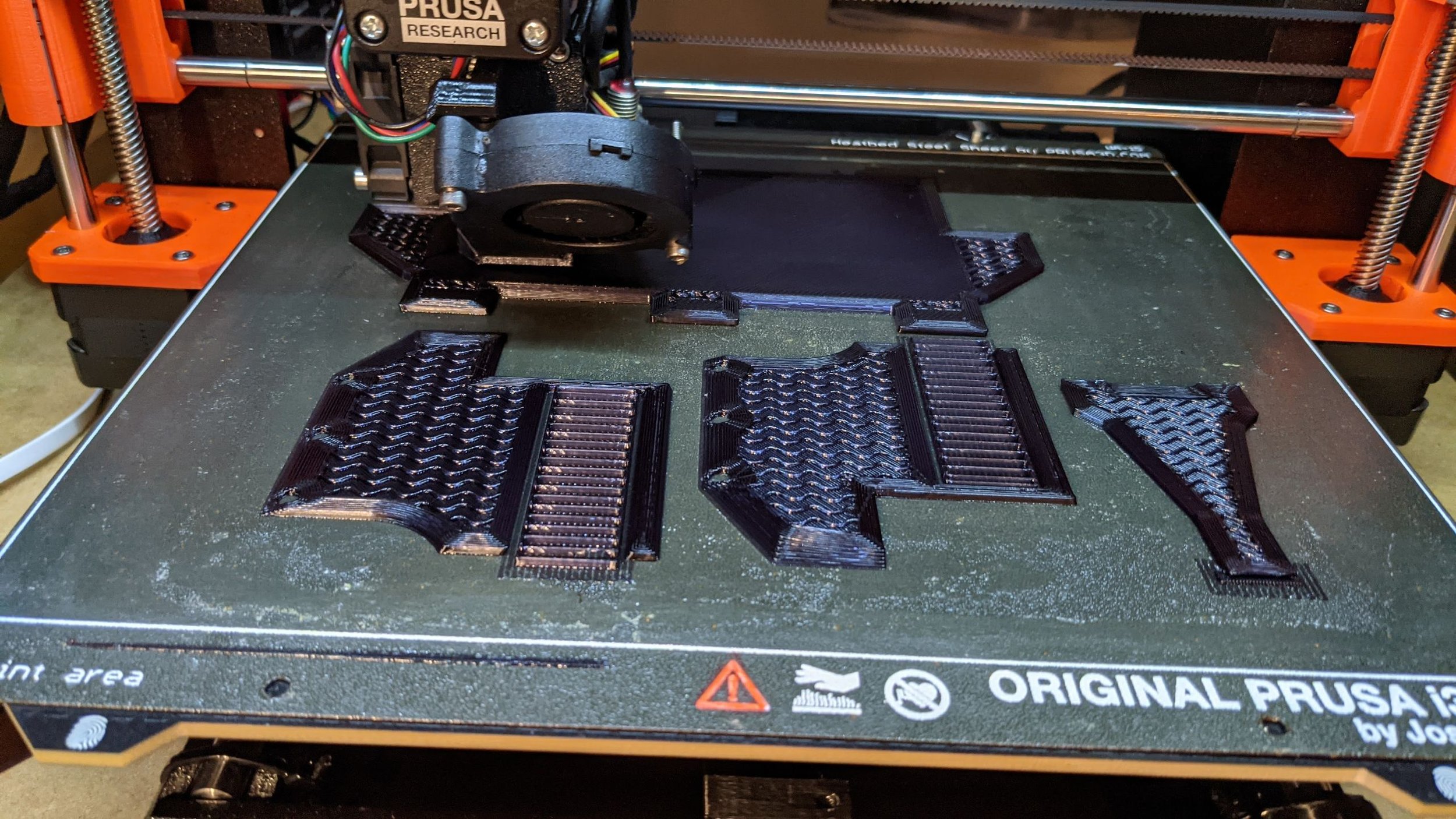

3D Printing: 3-Dimensional Printing also known as additive manufacturing, is the process of compiling thin layers of material, generally, polymers/plastics, to produce a 3-dimensional structure with ease. Designs are rendered in a Computer-Aided Design (CAD) or other 3D software. These designs can then be printed layer by layer producing intricate shapes and designs that would prove challenging or impossible when done by hand. For more information, see here. Check out my own 3D printing service to get parts printed without spending hundreds on your own 3D printer!

Prusa Mk3S 3D Printer, printing Taulman Alloy 910 Nylon parts. Click here to check out our 3D printing commission service!

Prusa Mk3S 3D Printer, printing Taulman Alloy 910 Nylon parts. Click here to check out our 3D printing commission service!

CAD design tools are required to outsource your parts to digital fabrication such as 3D printing, CNC machining and laser cutting. Here is an example of a technical drawing of the Just ‘Cuz 12mm Hex Hubs used to outsource for CNC machining.

CAD design tools are required to outsource your parts to digital fabrication such as 3D printing, CNC machining and laser cutting. Here is an example of a technical drawing of the Just ‘Cuz 12mm Hex Hubs used to outsource for CNC machining.Computer-Aided Manufacturing (CAM): In automating the manufacturing process Computer-Aided Manufacturing (CAM) may be used. CAM is the process of using computer-controlled machinery and software to increase the efficiency of the process and decrease the need for human intervention. While CAD focuses on the design of the product, CAM focuses on how it is made.

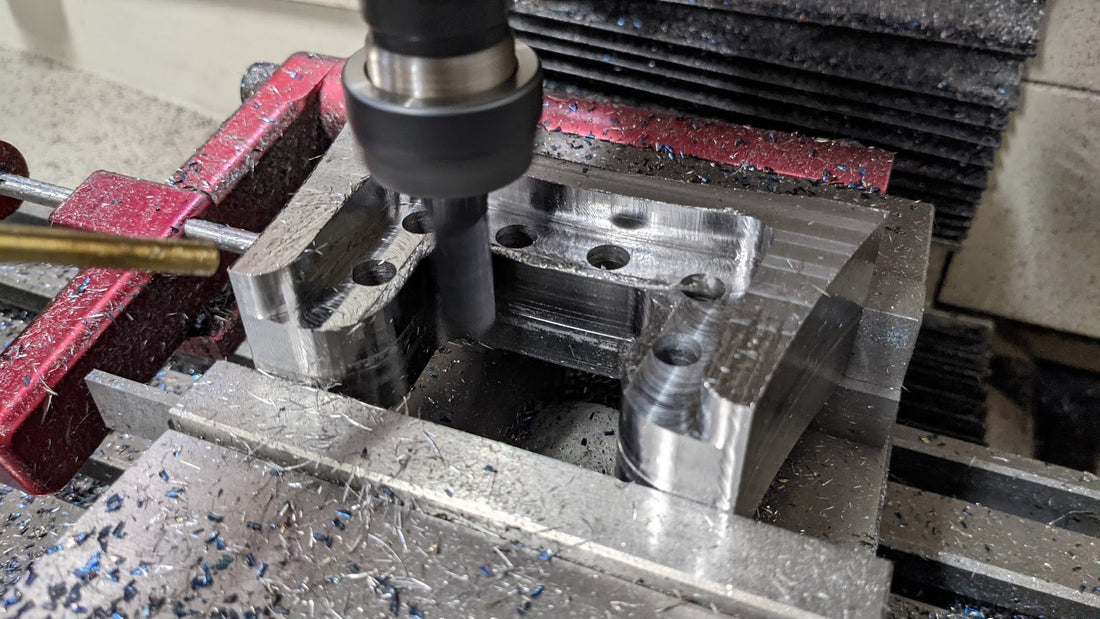

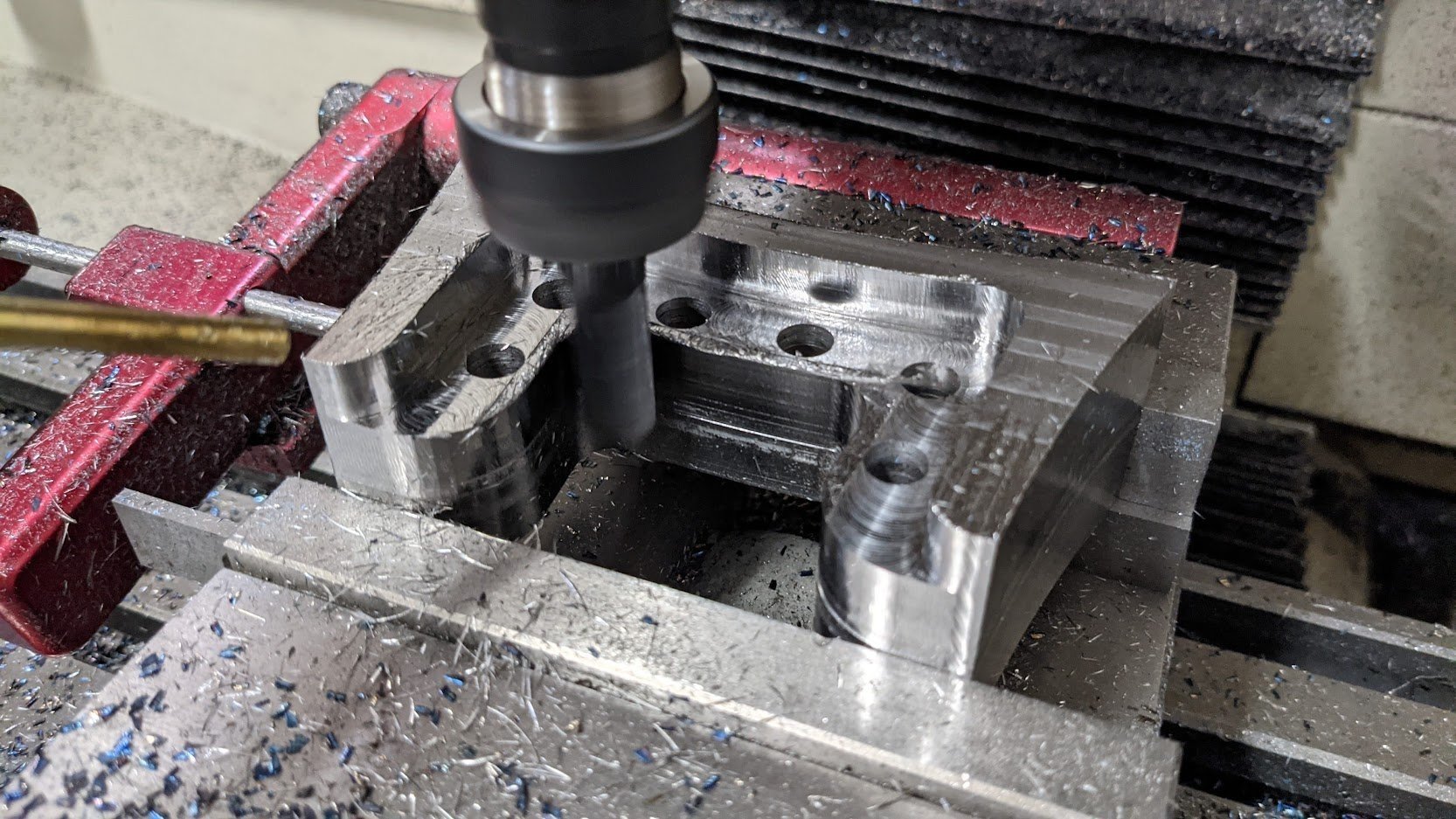

CNC Milling an S7 tool steel block for Bloodsport’s Club Sandwich weapon tooth (August 2021)

CNC Machining: CNC machining is often referred to as CNC Milling or CNC Routing, or just CNC. CNC machining is a subtractive manufacturing technology. In CNC, material is removed from a solid block using a variety of cutting tools that rotate at high speed—thousands of RPM—to produce a part based on a CAD model. Both metals and plastics can be CNC machined. See here for more details. CNC machining is often a last resort as it tends to be very expensive if you cannot do it yourself, and the equipment needed costs orders of magnitude more than 3D printers.

ESC (Electronic Speed Controller): ESCs or Electronic speed controllers, sometimes called motor controllers, take power from a battery, signals from a receiver, and output power to a motor in order to command its speed and change its direction. These are a fundamental part of any robotic system. Matching the voltage and current ratings on your ESCs to that of your battery and motors is essential.

ESCs come in many forms with lots of brand names. There are however a few things to look out for.

- Usually you need to buy a brushed ESC for a brushed motor or brushless ESC for a brushless motor. Brushed motors spin when any voltage is applied to their two terminals or wires, they never have more than 2 wires to receive power. Flipping the direction of the current lets them reverse direction, and no ESC is necessary if all you need is the motor to be on at 100% all the time.

- Brushless motors however, are all technically 3 phase AC motors, and require a suitable brushless ESC to time pulses to the 3 wires in order to rotate at all in either direction or at any speed.

- The most commonly used standard brushless ESCs have firmware called either AM32, BlHeli_32, or BlHeli_S. There is no standard firmware for brushed motors so each brushed ESC can behave very differently.

- There are a few brushless ESCs with firmware that allows them to switch to a brushed mode with a USB programmer. This is because having the ability to control voltage pulses for 3 wires means having the hardware for 2. The two main firmwares that support this in 2024 are VESC (predominantly for 30 lb and larger bots, often used in Battlebots) and AM32 (which is used on tiny drone ESCs common in 1lb up to 30 lb robots.

- Note VESC and AM32 ESCs are almost never sold out of the box with a brushed mode enabled, and you will almost always need a programmer for driving a brushed motor. If you connect the wrong kind of motor to your ESC you will probably destroy the ESC, motor, or both almost instantly!!!

- Unfortunately nearly all of the motors and ESCs that we use for 3lb and smaller bots are designed for use in RC cars, appliances, and drones, which are an extremely different use case from combat. This means the current ratings on ESCs aren't always very helpful. I recommend you buy a brushless ESC with at least 25% higher current rating than your application requires.

Lead time: Lead time is the latency between a customer's initial purchase and the delivery of the product. It is summed up as the total time a customer must wait to receive a product after placing an order. Lead time can be broken down into specific intervals through the manufacturing process including order preparation, setup time, run time, production time and inspection time. By breaking down lead time, managers can examine points in production where there are inefficiencies.

LiPo Battery: LiPo stands for Lithium Polymer Battery and it is the most common type used in drones, RC cars and planes, and combat robots. LiPo batteries are extremely power dense, but due to their chemistry are also extremely flammable and dangerous if mishandled. Please read this article for more details.

A selection of ESCs, LiPo batteries and motors alongside Division and Shrapnel Mine. Click for an electronics tutorial video!

Off-the-shelf: Off-the-shelf or COTS (Consumer Off The shelf) is a product that is sold by the manufacturer as it is produced with no additional changes or modifications. Products that are off-the-shelf there is no need for engineering design services or manufacturing changes, the product is ready to be sold as it was originally designed.

Rapid prototyping: Rapid prototyping is a technique used to quickly produce a model of a part or assembly. Commonly, 3D printing or additive manufacturing is used to rapidly produce scale models. In some cases, these prototype parts can be used in a final product or robot without many modifications.

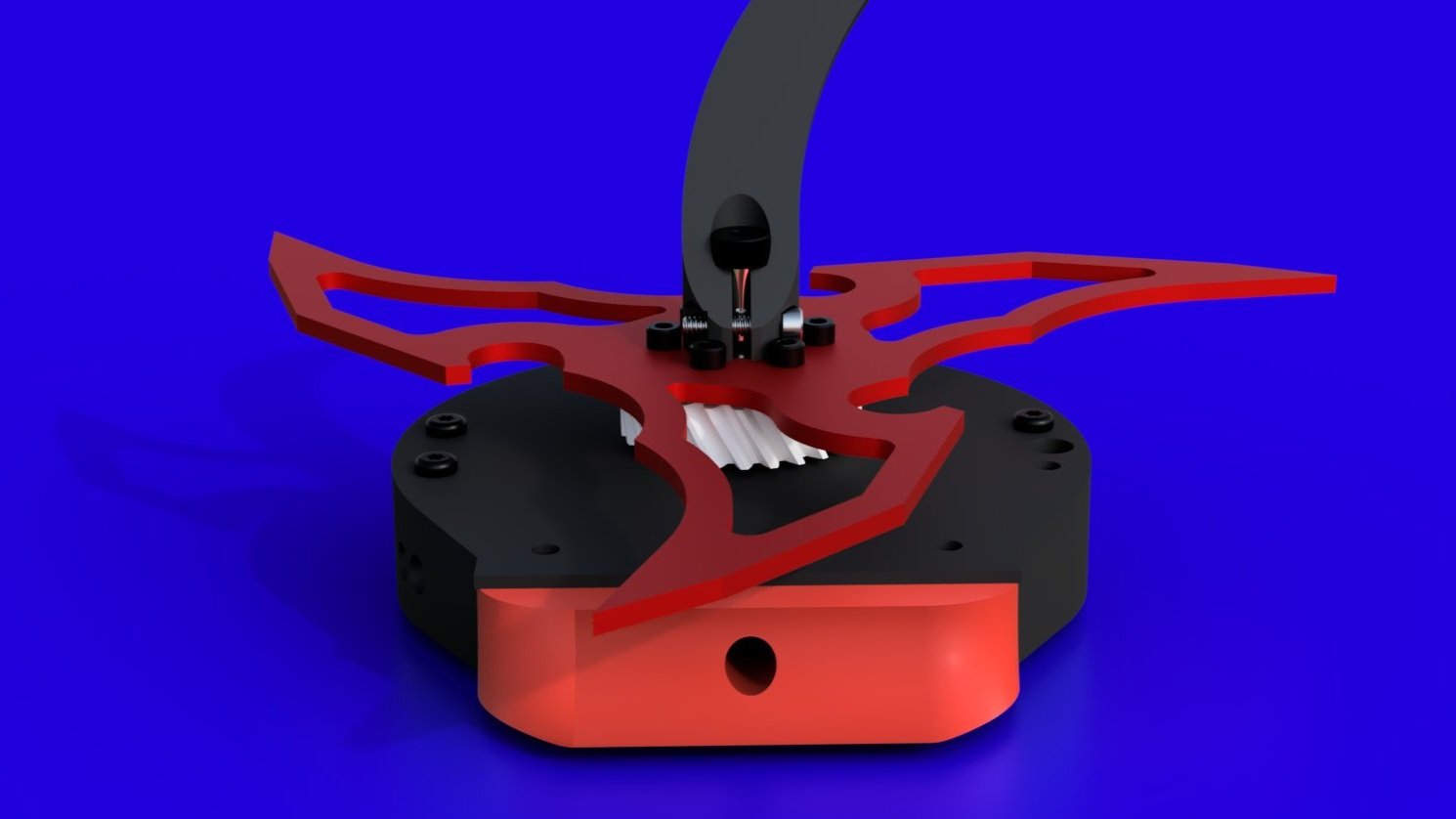

Render: Renders are computer generated images which are made to look more photorealistic than plain CAD views by simulating the texture, reflectivity and transmissivity of different materials and the way light bounces off them, as well as providing a more camera-like perspective view. Renders are commonly used for product sales pages and Battlebots applications.

An example of a render of Mini Mulcher, a 1-pound combat robot. Note the realistic shadows and reflections.

Spinner: Spinners refer primarily to any sort of robot with a kinetic energy storing spinning weapon, like a horizontal or vertical bar spinner, disk spinner, drum spinner, beater bar, etc. Saws are a bit of a grey area here as they are not kinetic energy-storing weapons.

Torque: Torque is just rotational force. It is given in several units of measurement that are always a force times a distance. Newton-meters (Nm), ounce force inches (oz-in or ozf-in), pound-feet (lb-ft or lbf-ft) etc. Torque is important to calculate acceleration from a given motor and wheel diameter, or how fast a weapon can spin up, and also how much weight can be lifted on the end of an arm of a given length. Torque is a very fundamental concept both in physics in general and in robot design.

Toughness: Toughness describes a material's ability to handle abuse. Often this is shortened from Impact Toughness, the measure of how well a material can survive impacts.

Properties, Units, Values

Current (I): Current is a measure of how much energy is flowing through a circuit or component. Its unit is A or “Amps” or Amperes. Current is generally ‘drawn’ by ESCs and motors, it is not ‘pushed’ by the battery. Your battery needs to be able to supply the maximum current demand of the system, but there is no real harm in having more battery capacity or discharge current capacity than you need. For a motor, torque is dependent on current.

KE (Kinetic Energy): Kinetic Energy, a measure of the total energy stored. Typically this is measured in Joules (J) or kilo-Joules (kJ). A 3lb beetleweight might have 200-500J of kinetic energy stored in a spinner, while Battlebots can surpass 50,000J!

kT (Torque Constant): kT represents the torque-per-amp for a motor. It is pretty self explanatory, max current * kT = max torque.

kV (Speed Constant): kV is a term that stands for the speed constant and it is essentially RPM per volt. For a given brushless motor, the max speed it can achieve is kV * the battery voltage.

MOI (Moment of Inertia): MOI or Moment of Inertia is a physical property of a mass that describes how hard it is to rotate. This relates to how much kinetic energy a spinner can store. KE is porportional to 1/2 * MOI * (RPM^2)

Power (P): Power is a measure of the rate at which electrical or mechanical energy is output, usually measured in. 1 Watt is 1Volt * 1Amp. No motor or ESC or battery is 100% efficient so the mechanical output power is never 100% of the electrical input power to a motor. Some power is always lost as heat.

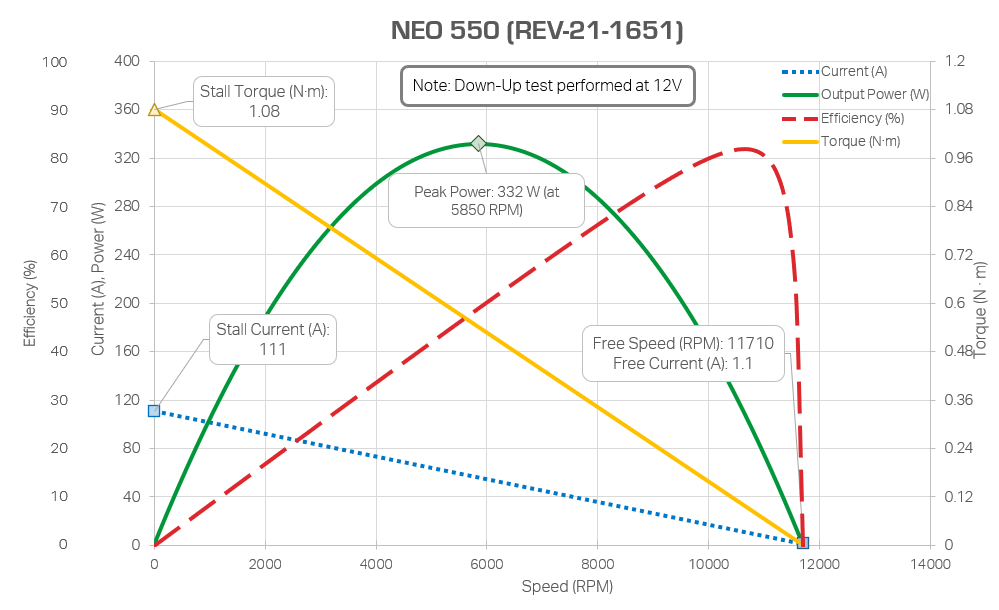

Example of a motor power curve chart. Note the relationship between speed (RPM), torque and power. This is for the Rev Robotics NEO 550 brushless motor.

RPM (revolutions per minute): RPM is a measure of rotational speed, Its usually given as the rotational speed of a motor or output shaft of a gearbox at maximum speed. For brushless motors, max RPM = kV * Voltage.

Voltage (V): Voltage is a measure of electrical potential energy measured in Volts. Matching the voltage of your system to the acceptable range for your components will ensure they work together correctly. Too high and you will release the magic smoke. Too low and things will not turn on or work properly, but will usually not be damaged.

Materials

Some links to materials discussed below are affiliate links.

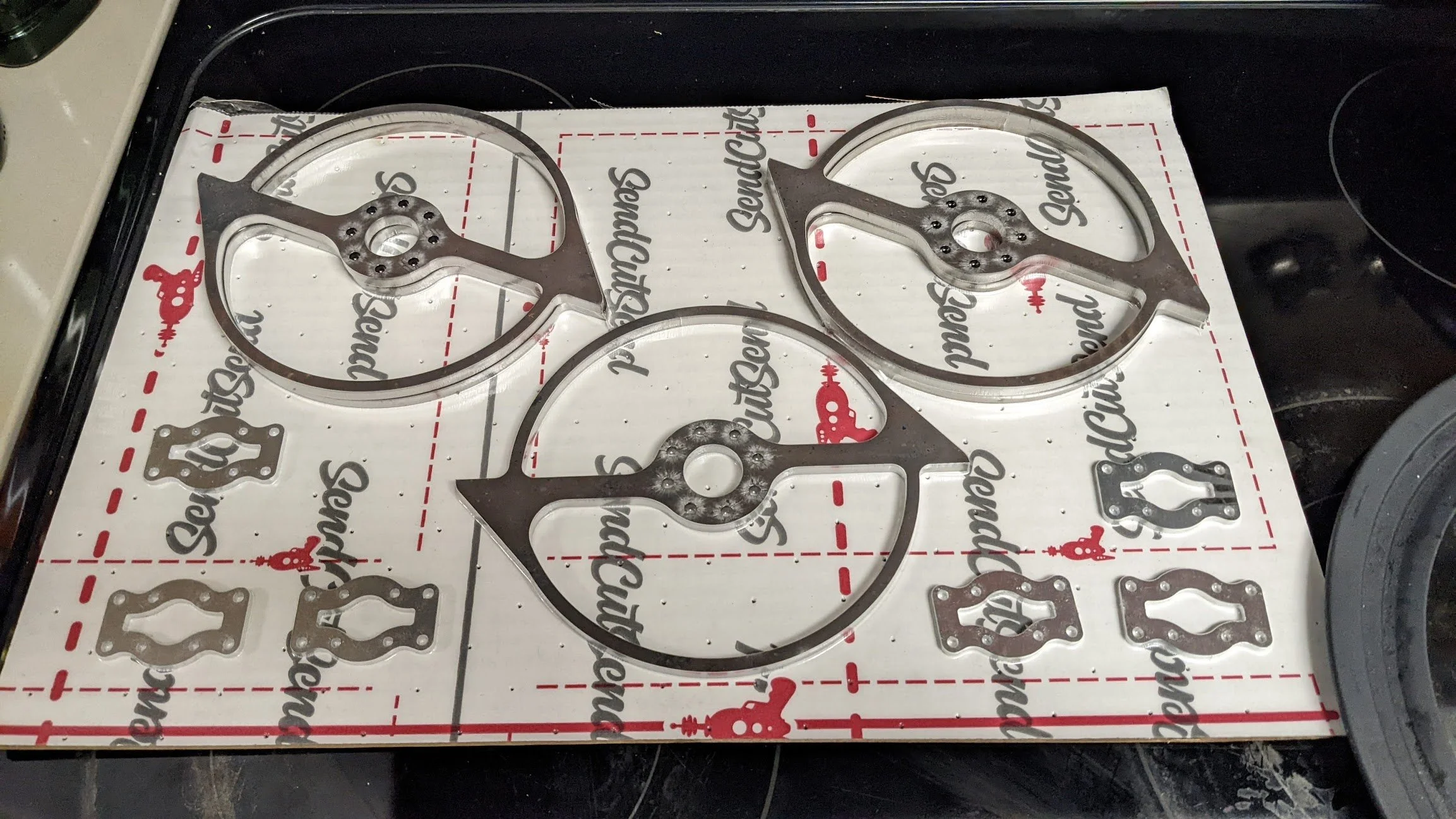

Abrasion Resistant Steel [AR500, etc]: AR or Abrasion Resistant steels are wear-resistant plates. These steels are not very consistent but generally, the surface hardness is measured as the stated number on the Brinnel hardness scale (AR500 being 500 Brinnel). These plates can be through hardened for thinner sheets but thicker may only be hardened on the top and bottom surfaces, with the inside being fairly soft. Still, AR500 is the material of choice for almost all flat, thin weapons in bots 30lbs down to 150 grams due to its low cost and design freedom from laser cutting services like Send Cut Send.

ABS: ABS or Acrylonitrile butadiene styrene is a 3D printable plastic that gained popularity in the early days of 3D printing. It actually is very difficult to print, however, and PLA has taken over as the dominant filament o choice. ABS produces extremely noxious fumes, its styrene content makes these acutely toxic, and it warps easily and has trouble sticking to some printer beds. ASA is a much better choice.

ASA: ASA provides an alternative to ABS for outdoor applications needing UV and weather resistance while boasting mechanical and temperature resistant properties as ABS and being easier to print. Anything you might use ABS for, you should probably use ASA instead.

Composites: Composites are materials composed of two or more materials with significant differences in chemical or physical properties. Examples include Carbon-Fiber- and Glass-Fiber-filled Nylon, or other fiber-reinforced polymers. These materials result in a product that behaves differently than the individual materials they are composed of. For instance, CF-Nylon is more brittle and likely to crack on impact than plain Nylon, but it can survive higher temperatures, is stiffer, and has a higher tensile strength

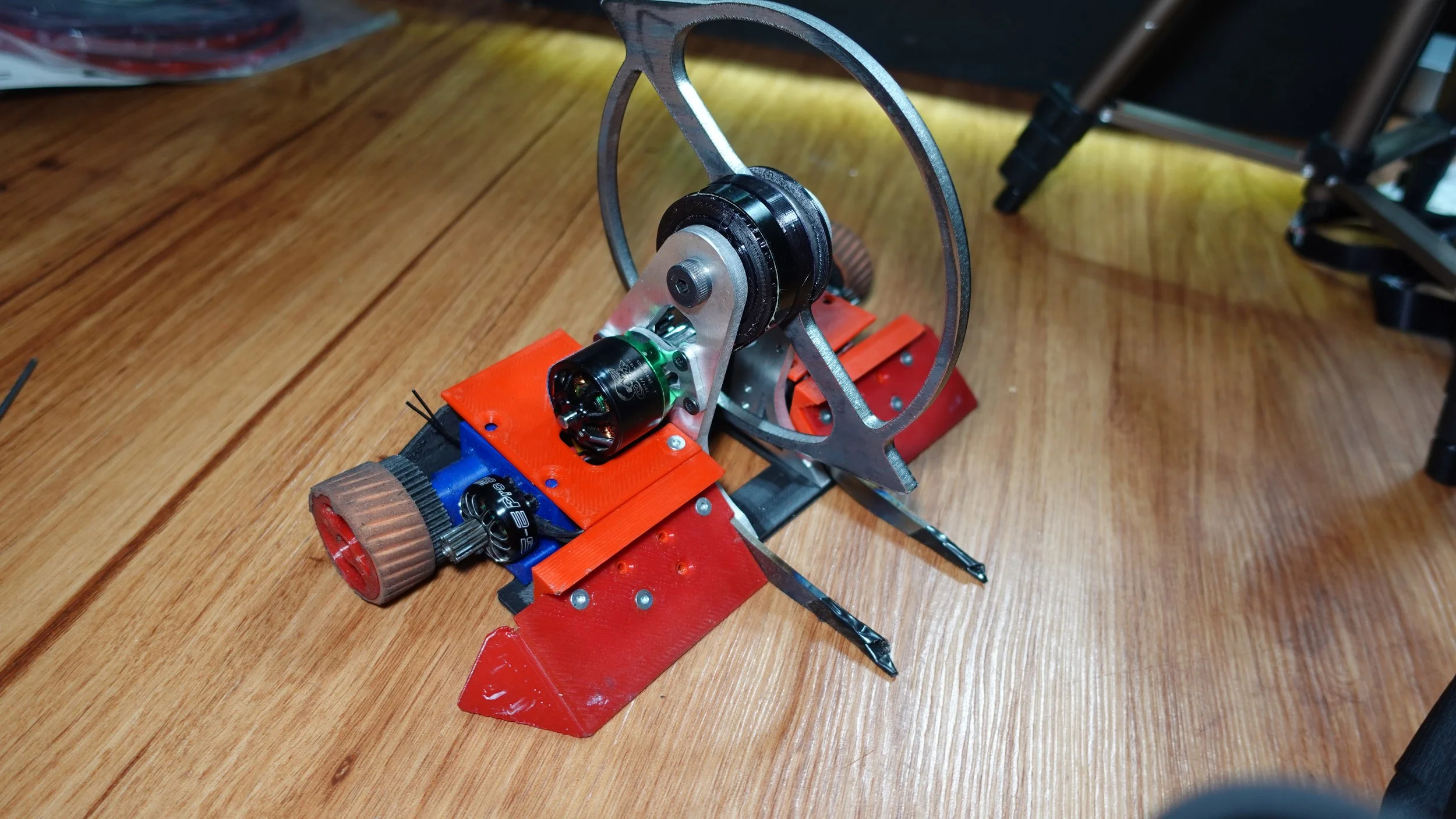

Division (3lb beetleweight) uses a lot of different materials including composite CF-Nylon drive gears, and Carbon Fiber sheet top panels and an aluminum chassis.

Carbon Fiber: Normally when someone says "carbon fiber" in the combat robotics world they are referring to what in the industry is known as a "laminated sheet" of carbon fiber. This is a composite consisting of woven fabric sheets of carbon fibers in an interlocking or alternating pattern, and an epoxy resin binder which solidifies the layers together making an incredibly stiff, flat, and strong sheet of material. Generally carbon fiber sheets are cut using a CNC router with services like CNC Madness (based in Canada) or waterjet cut in some cases, though this is much more costly.

Delrin (Acetal, POM): Acetal, Delrin, and POM are all names for a similar class of materials, with Delrin being a brand name for Acetal Copolymer. Acetal is relatively stiff and brittle but quite low friction. It is not 3D printable on almost any machine.

G10 (FR4, Garolite, etc): G10 is a very common composite, it is essentially identical to carbon fiber except that instead of carbon the fibers are fiberglass. G10 is about half the price of carbon fiber sheets, and about 20% more dense, but it is less stiff and strong. It is also a bit less likely to crack and shatter across the entire sheet compared to CF, and tends to 'chip away' when hit. SSP Kit lids are made of G10.

Hardox: Similar to AR steels, Hardox is a prehardened steel, which is always through-hardened to create a consistent, very hard, and durable steel even in thicker sheets. Hardox is difficult and expensive to source within the US but easier overseas.

HDPE: HDPE is High-Density PolyEthylene and it’s used for milk jugs and cutting boards and lots of other durable goods. It is not 3D printable on almost any machine. HDPE is often the ‘poor man’s UHMW’ as it can be gotten cheap in the form of cutting boards and hacksawed into shape.

Nylon (PA): Nylon is a brand name for the PolyAmide polymer, and is a very durable engineering plastic widely used for all sorts of purposes like power tool casings, gears, pulleys, and more. Nylon is 3D printable although tricky and not all machines can handle the temperatures required. But it has superior impact toughness to almost any other rigid material. Nylon comes in various forms such as PA6, PA6/6, PA11 and PA12 with different properties.

PETG: PETG is Polyethylene Terephthalate Glycol is a very common 3D printable plastic. PET without glycol is what most plastic drink bottles are made from, as it is naturally clear, durable and recyclable. PETG is relatively easy to 3D print and has way better mechanical properties than PLA, but still much worse than Nylon. It varies wildly by brand with some being decent at taking impacts and others being super brittle.

PLA: PLA or PolyLactic Acid is one of the most widely used 3D printing plastics. PLA is very easy to print, but makes extremely weak, stiff parts with low-temperature resistance. For motion components, PETG is usually preferred. PLA is only useful as armor in the Plastic Ant class. PLA is a bioplastic often made from corn or sugarcane, unlike other plastics which are mainly petroleum-based. It varies wildly by brand and additives, but most additives make it even less durable.

PolyPropelene (PP): PolyPropylene is a hydrophobic polymer that has an excellent blend of mechanical properties. It is a little bit flexible and has great impact toughness while also being fairly strong and low friction. It is widely used for films, food packaging, bottle caps, and living hinges on plastic products. Polypropelene can be 3D printed, but only with specialized bed adhesives, as it doesn’t stick to most bed surfaces without special adhesives, and tends to warp easily. It doesn’t require being dried, however.

TPU: TPU or Thermoplastic Polyurethane is a class of flexible 3D printable materials that exhibit a wide range of properties. The shore hardness determines how hard and stiff it is, with the standard form being about shore 95A, which is rather rubbery and soft. TPU unlike other 3D printable rigid materials is squishy, bendy, and almost unbreakable on impact. Lower than shore 90A it becomes extremely difficult to print, but shore 95 can be printed (slowly) on almost any 3D printer. Direct Drive extruders have a much easier time with these flexible filaments. TPU has gained a lot of attention and widespread use in the Combat Robotics world.

Division V3 was largely prototyped using cheaper PETG before final parts were printed with Nylon, TPU and PolyPropelene, plus metal parts from titanium, aluminum and steel

UHMW: UHMW stands for Ultra-High Molecular Weight Polyethelene. This has longer polymer chains (larger molecules) than HDPE and is considerably more impact resistant and durable. It is not 3D printable on almost any machine. UHMW is slippery, more so than most plastics and is often used for chutes and containers in production environments.