Just 'Cuz Robotics

SSP CNC Machined Parts

SSP CNC Machined Parts

Share

Couldn't load pickup availability

SSP Kit CNC Machined Replacement Parts!

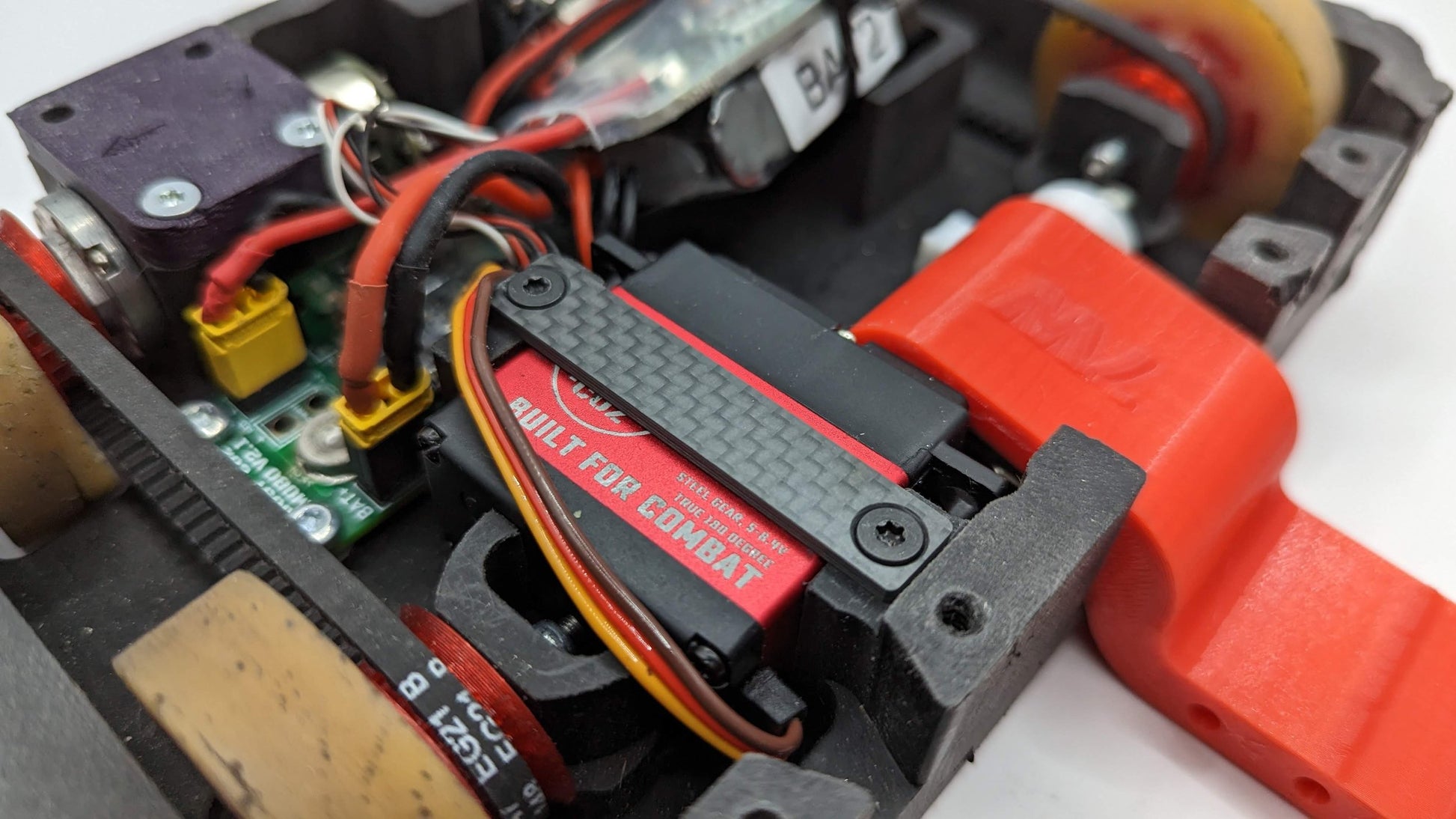

Many of these are the same exact components included with the base SSP kit. All of these are CNC machined to precision specifications by one of our chosen manufacturing partners.

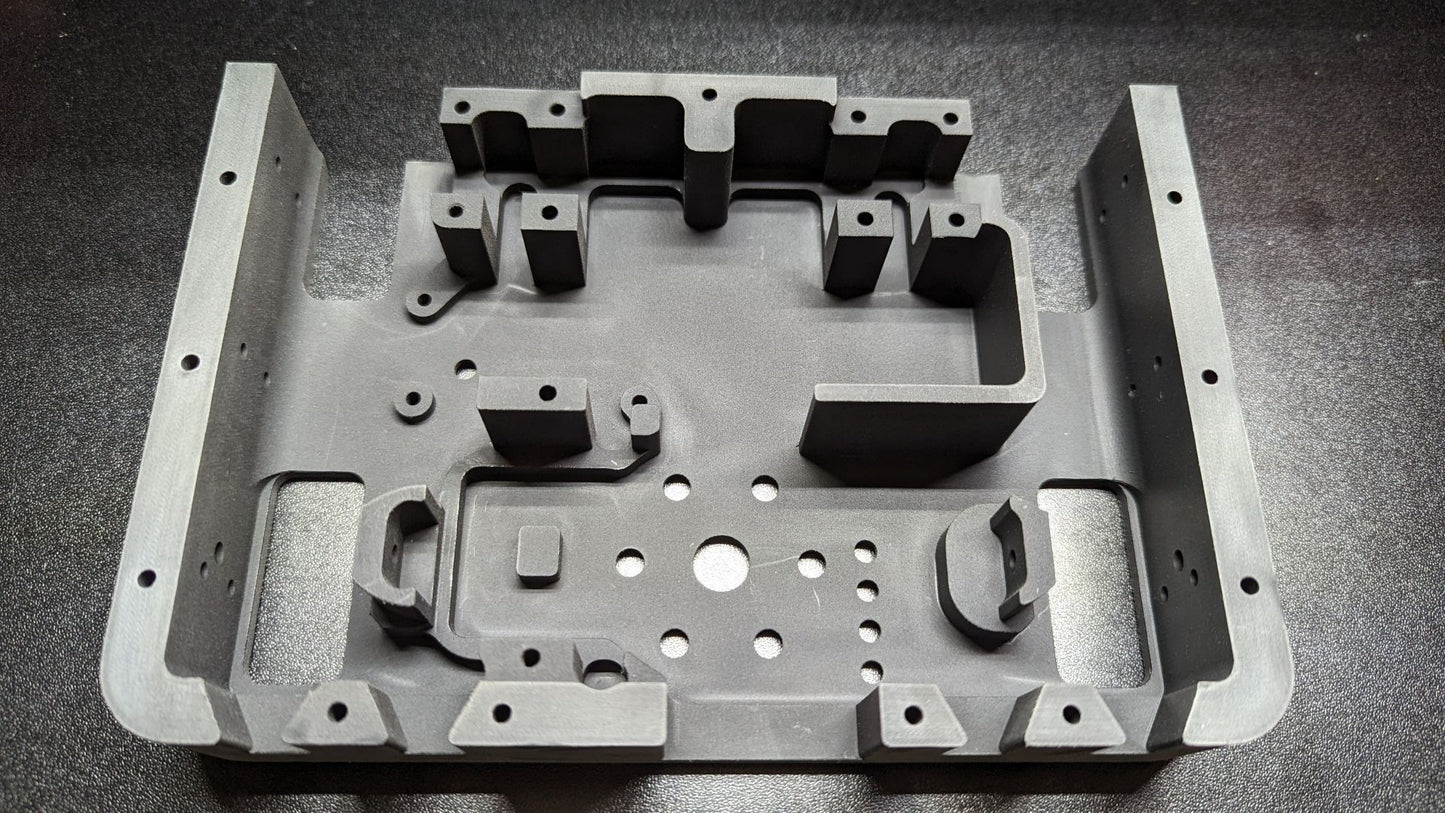

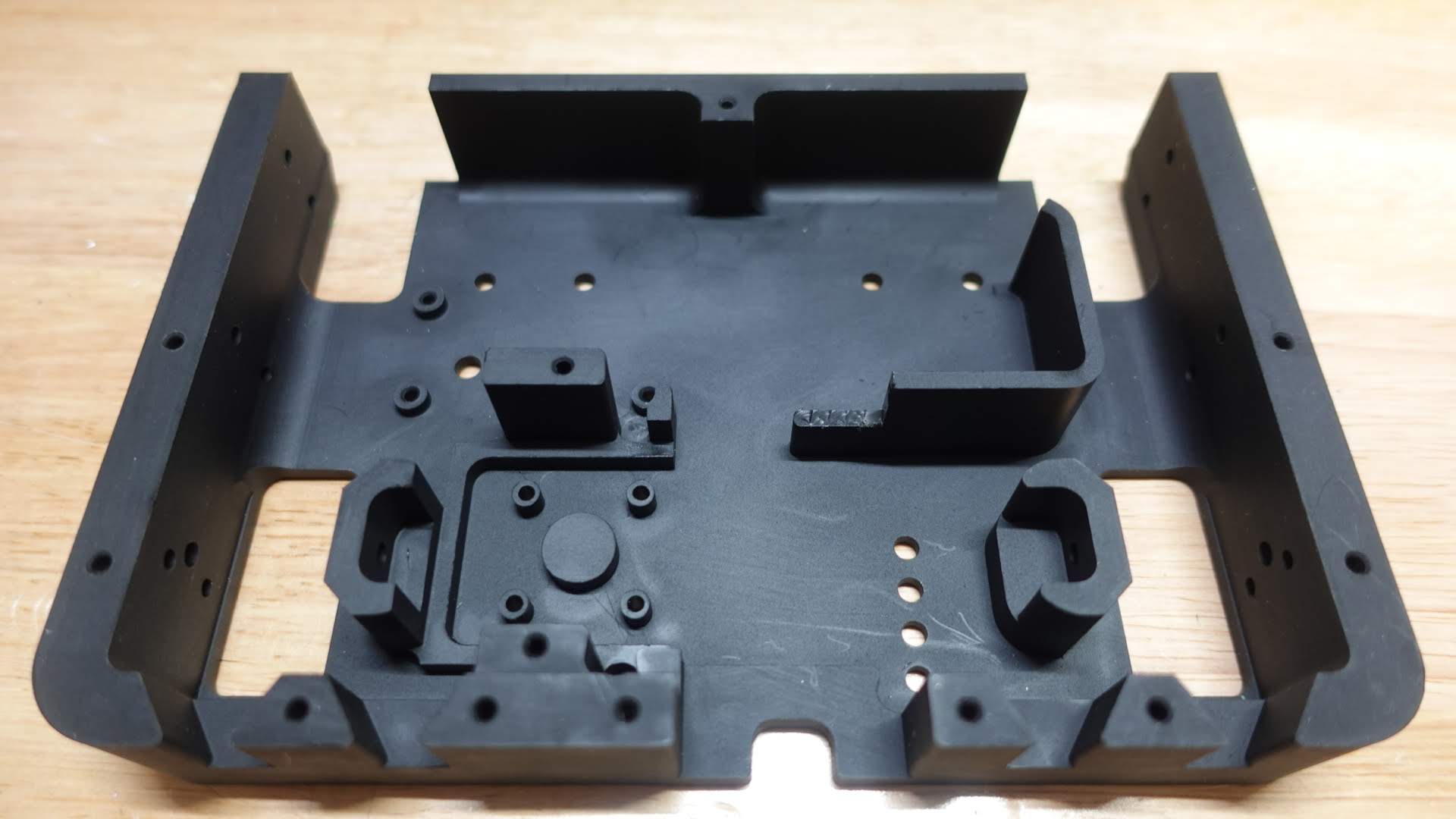

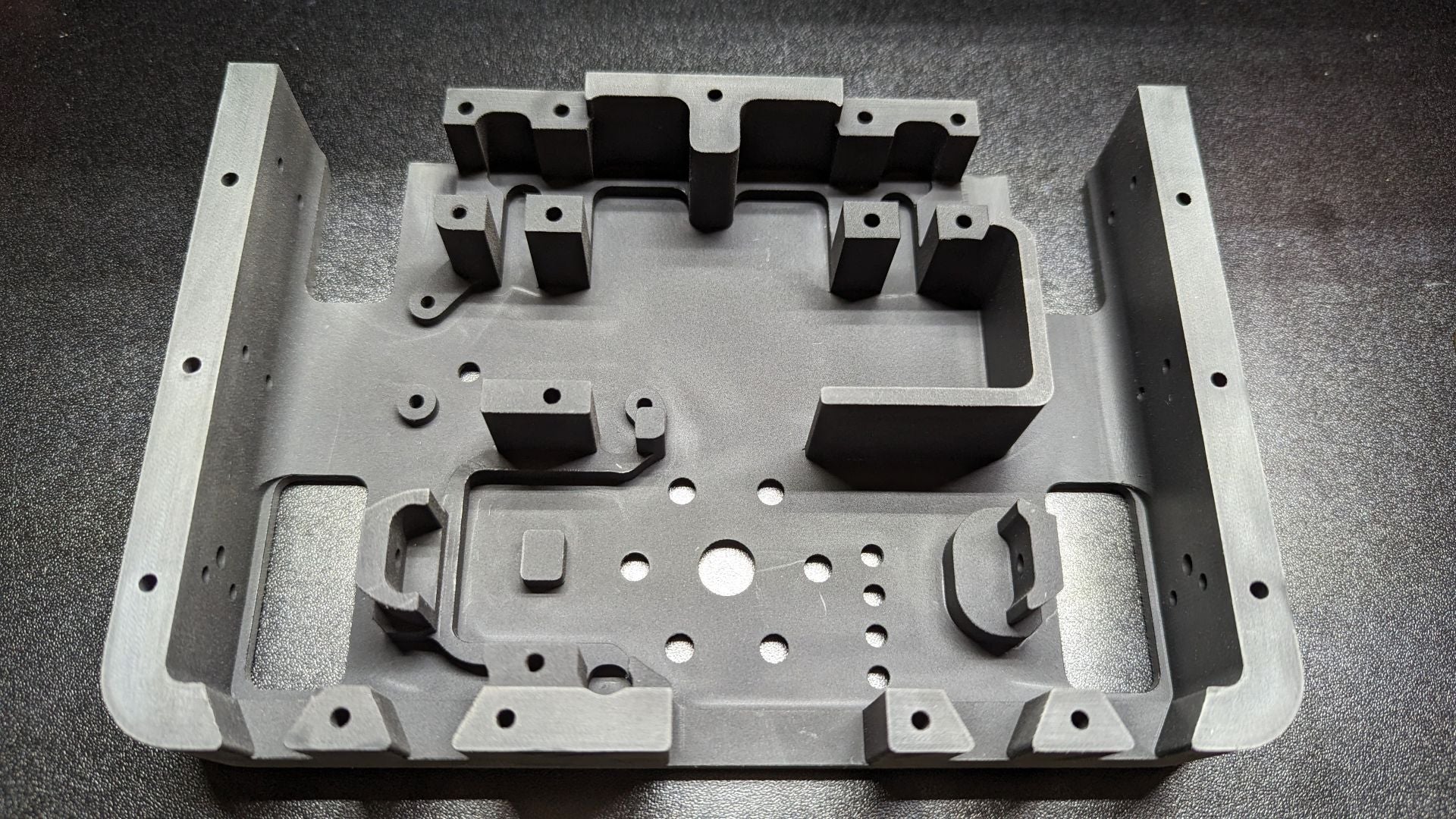

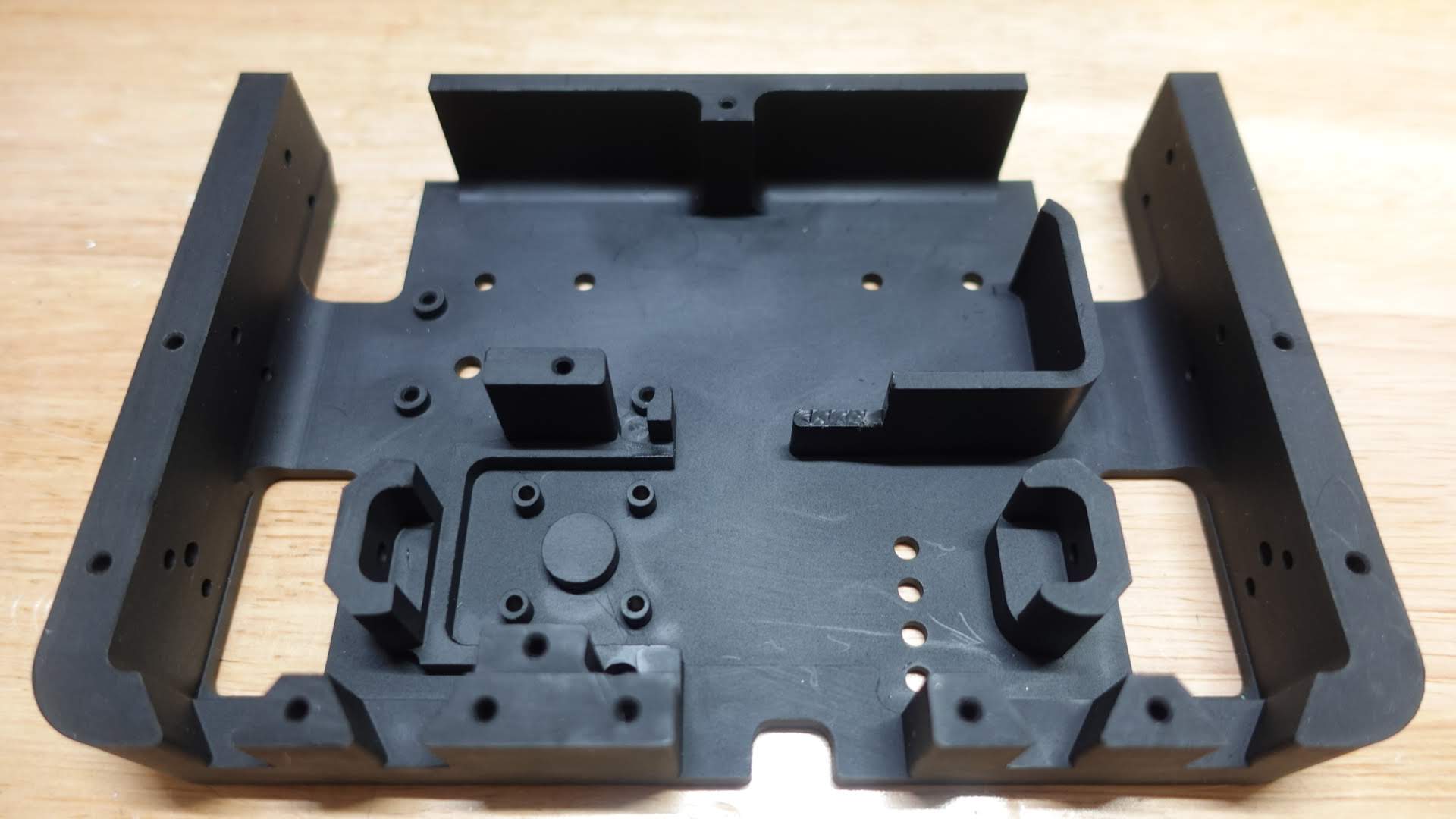

SSP Chassis are machined from a billet of UHMW (Ultra High Molecular Weight Polyethylene Plastic), for unmatched durability and impact toughness, without sacrificing the ability for anyone to drill or cut away to modify it at home. This plastic is widely used in robot combat and in almost every top-tier 3lb robot at NHRL.

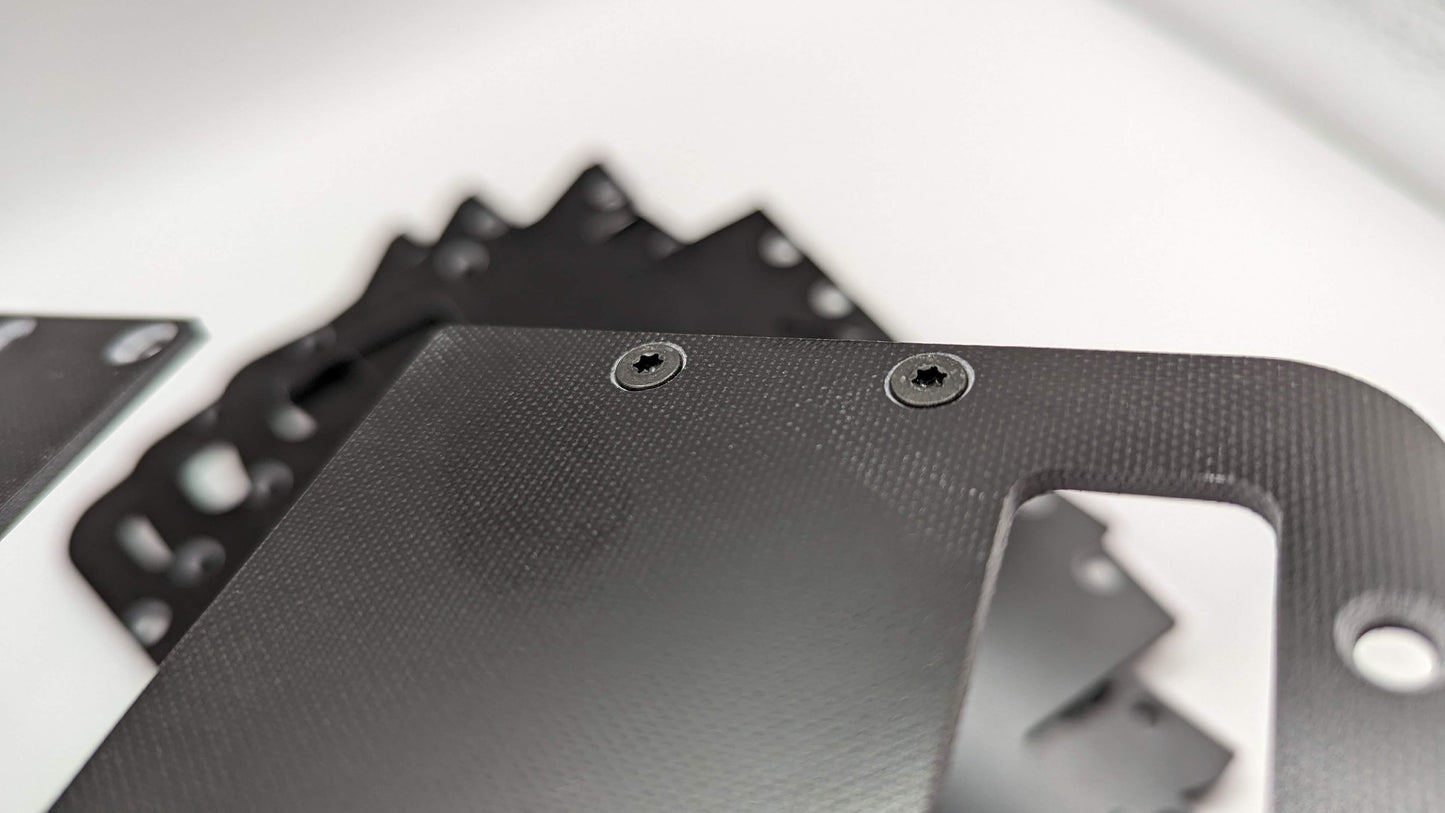

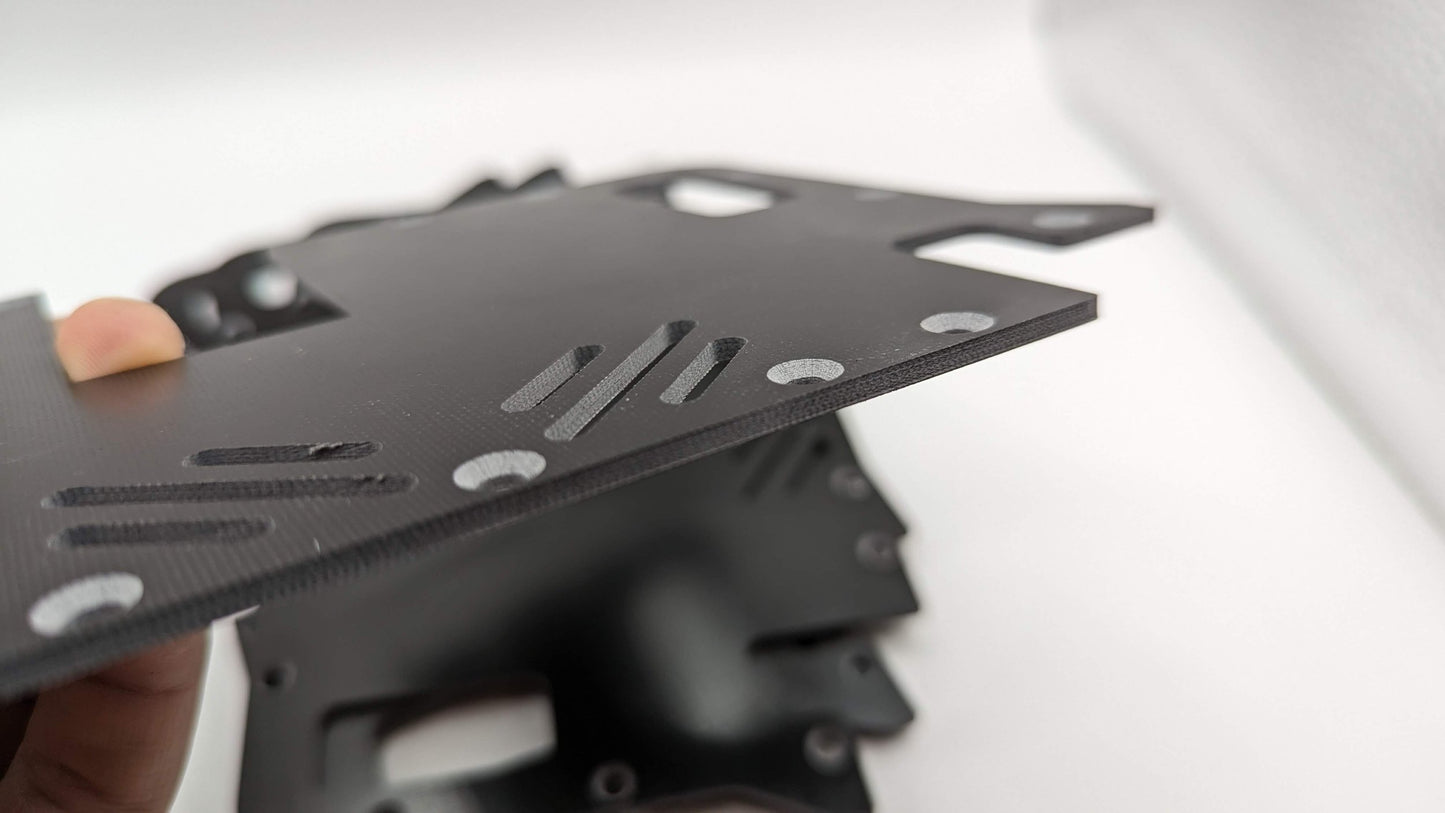

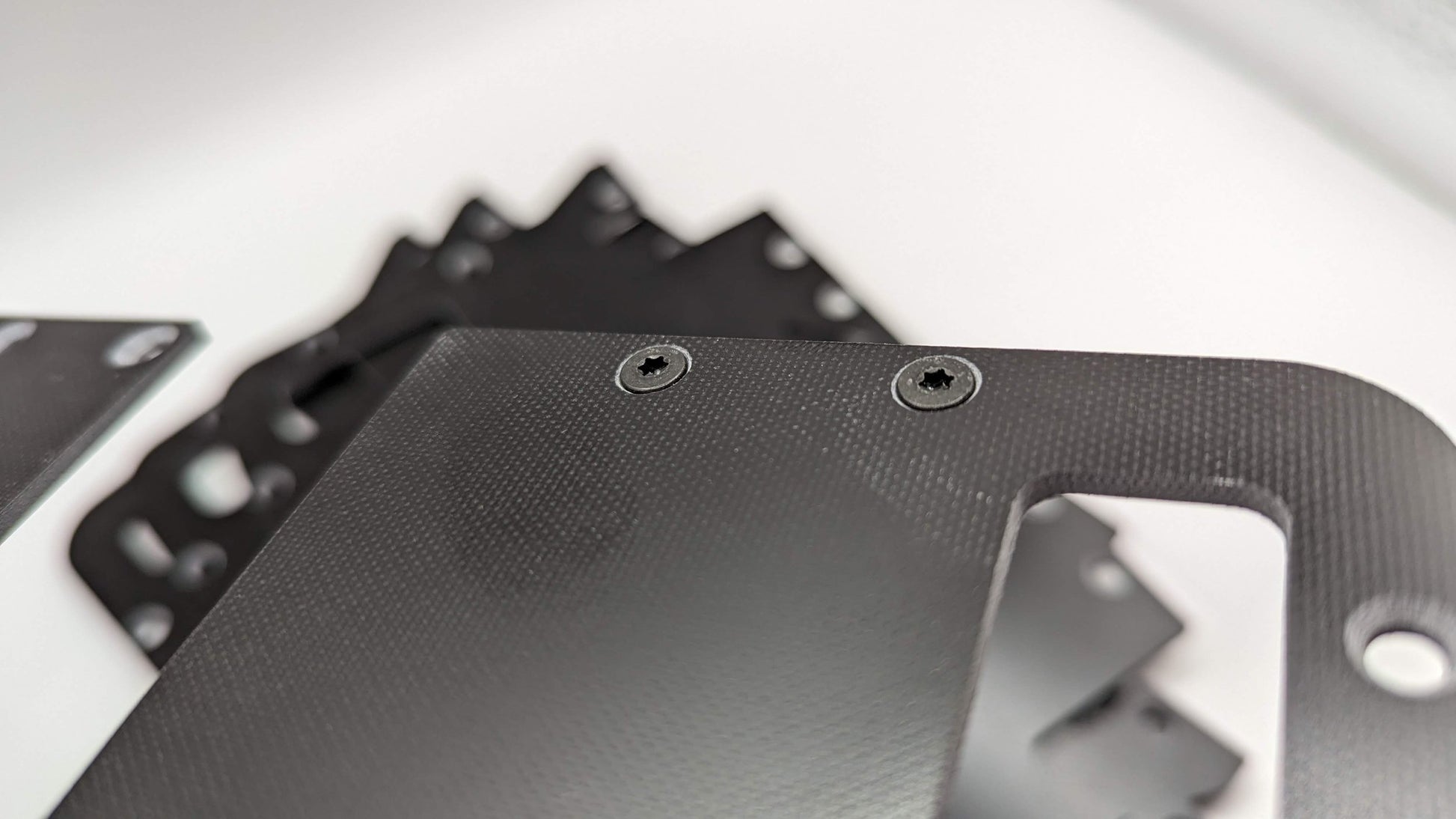

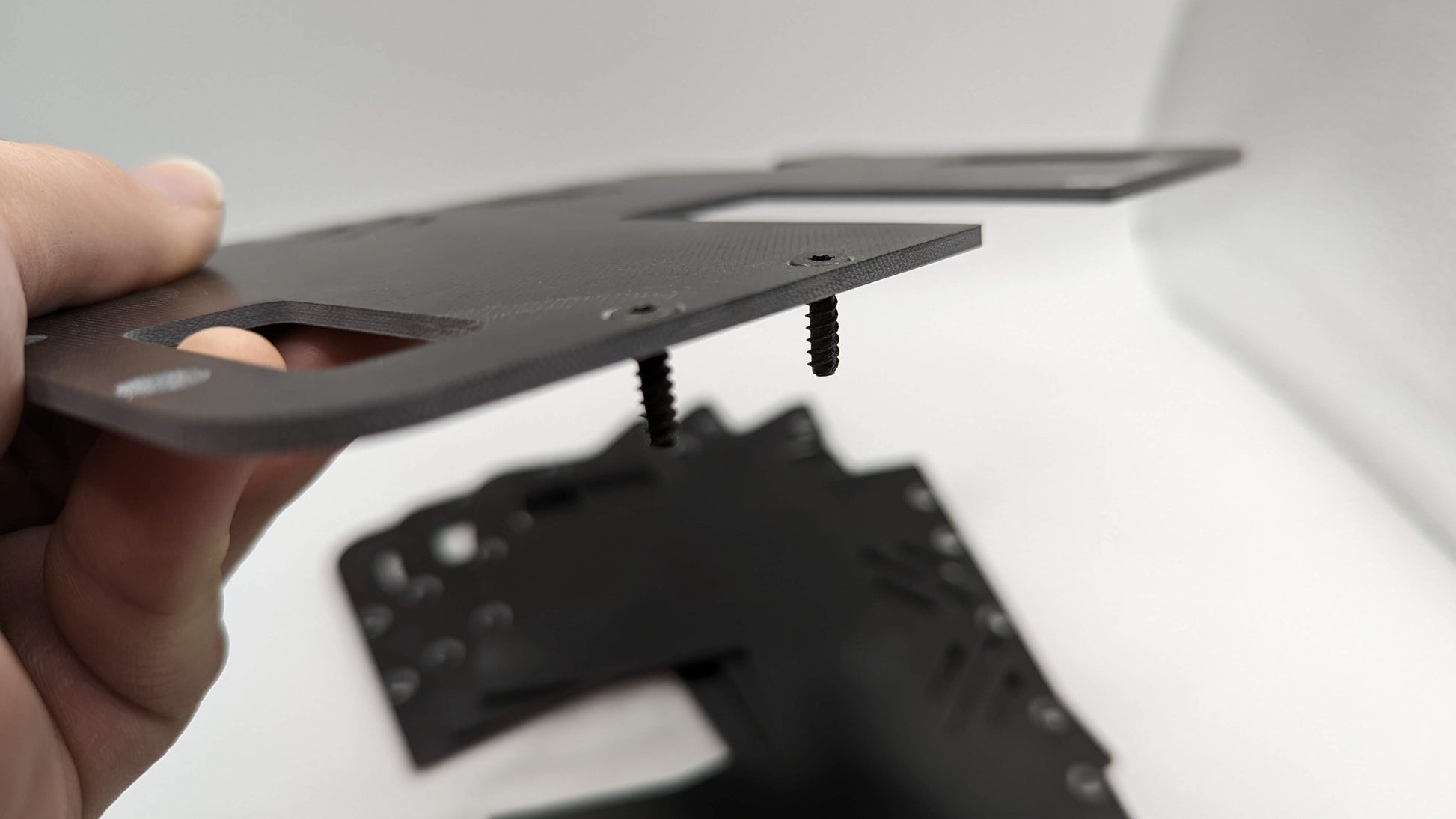

SSP 2.0 is here! While most parts are forward and backward compatible, the 2.0 chassis, servo retainers, and lid have changed. The 2.0 kit does not have countersunk holes for screws to maintain the most strength possible in composite parts, and the lids have a different set of holes on the back half.

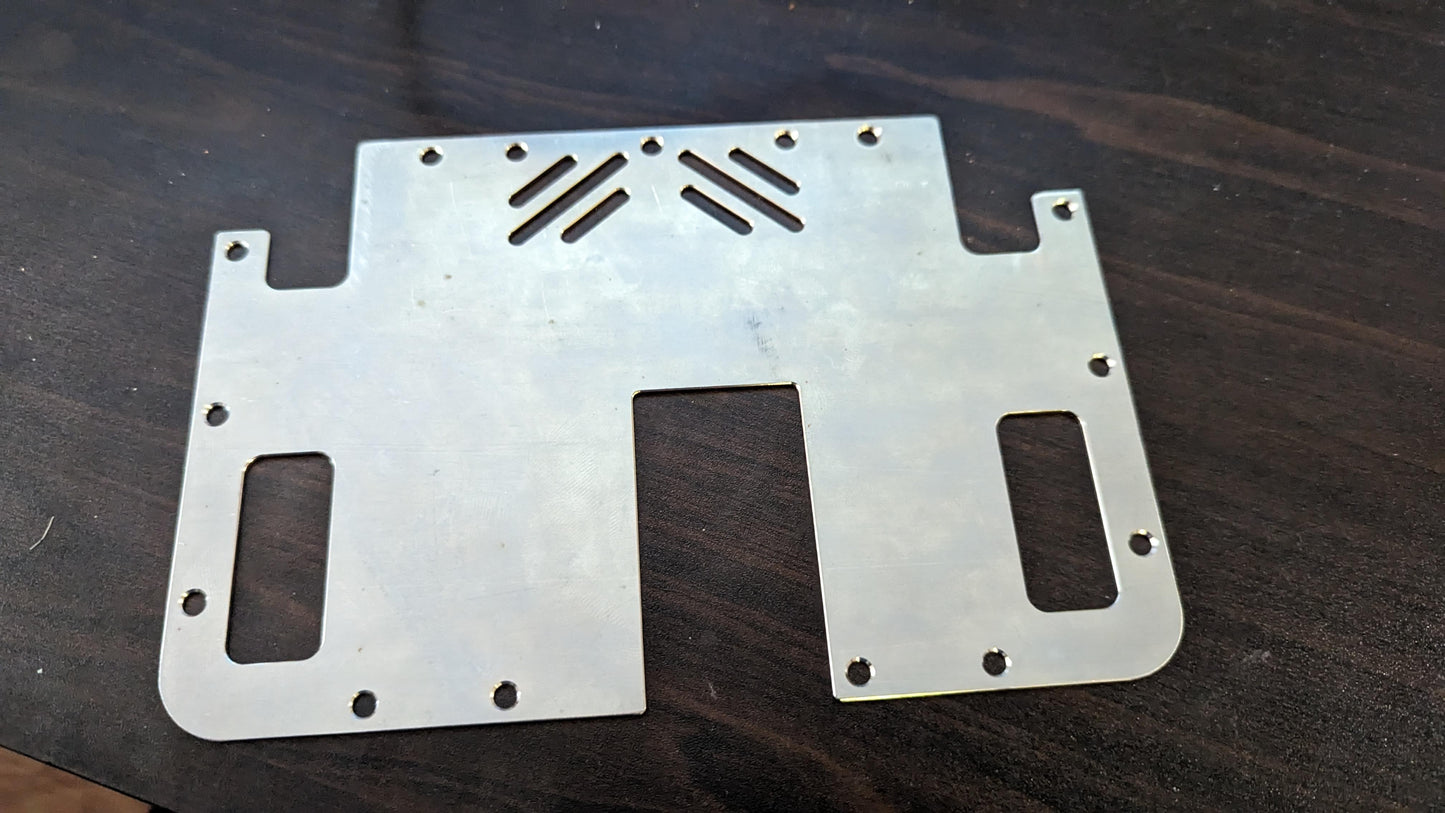

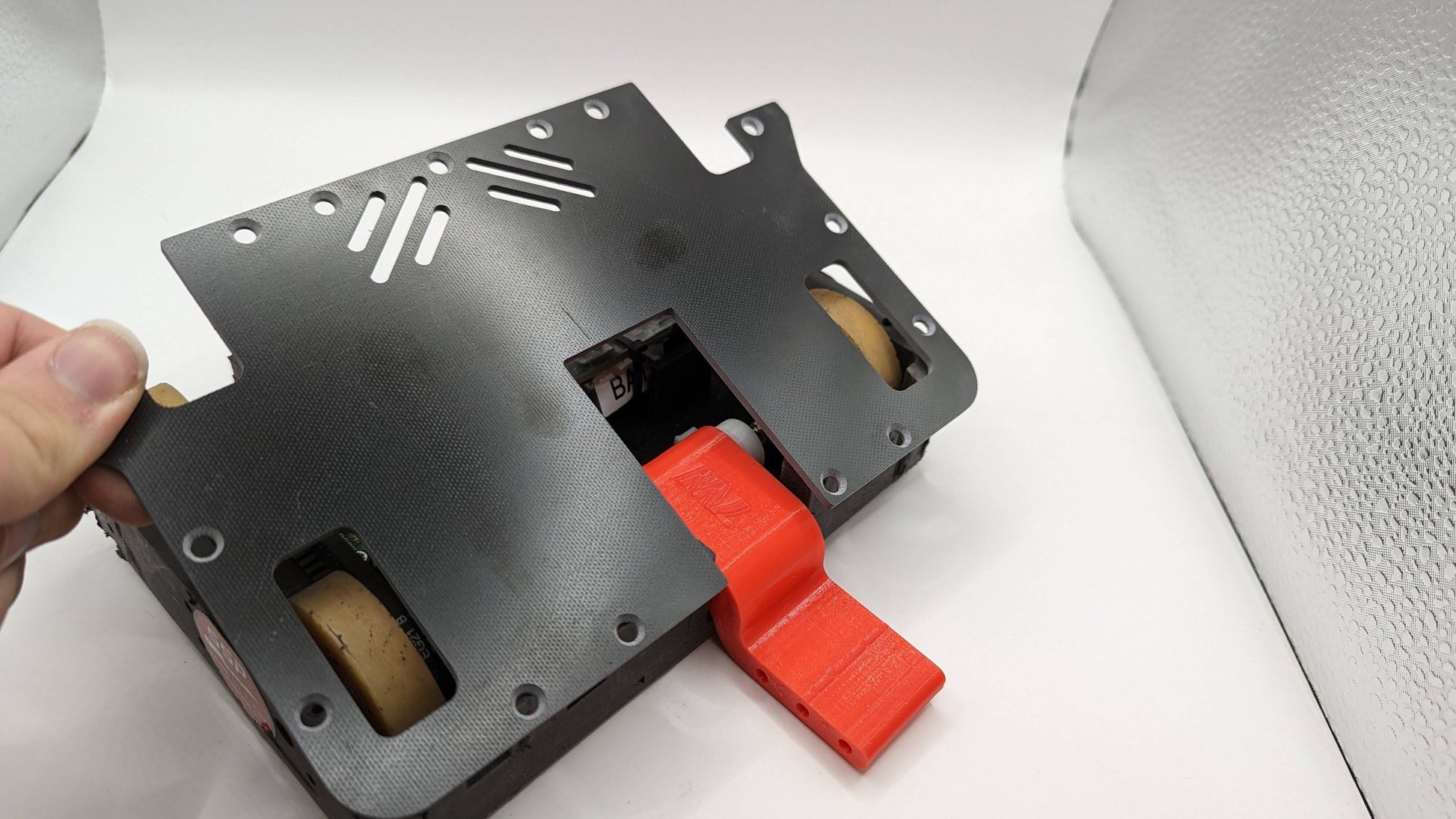

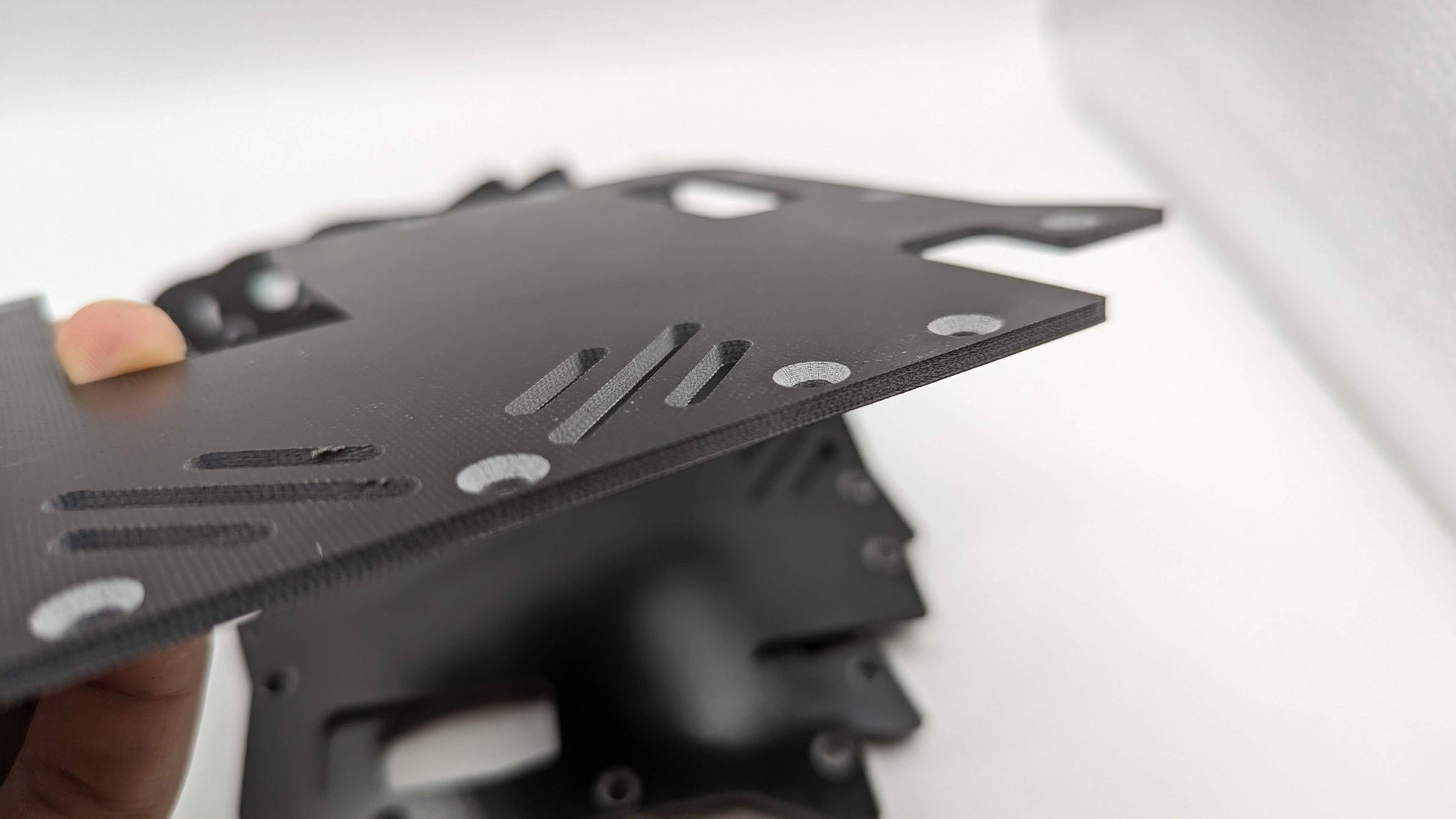

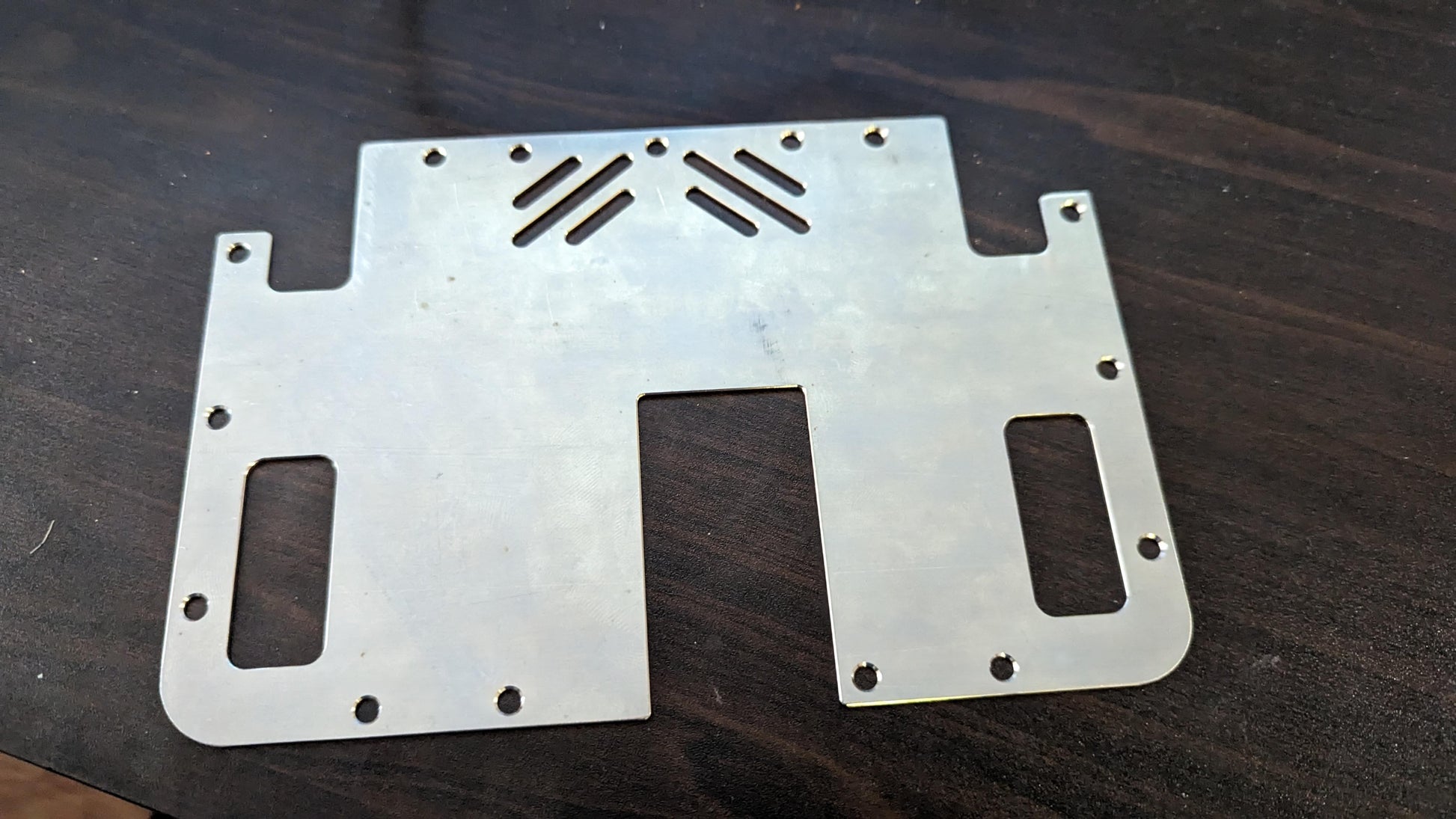

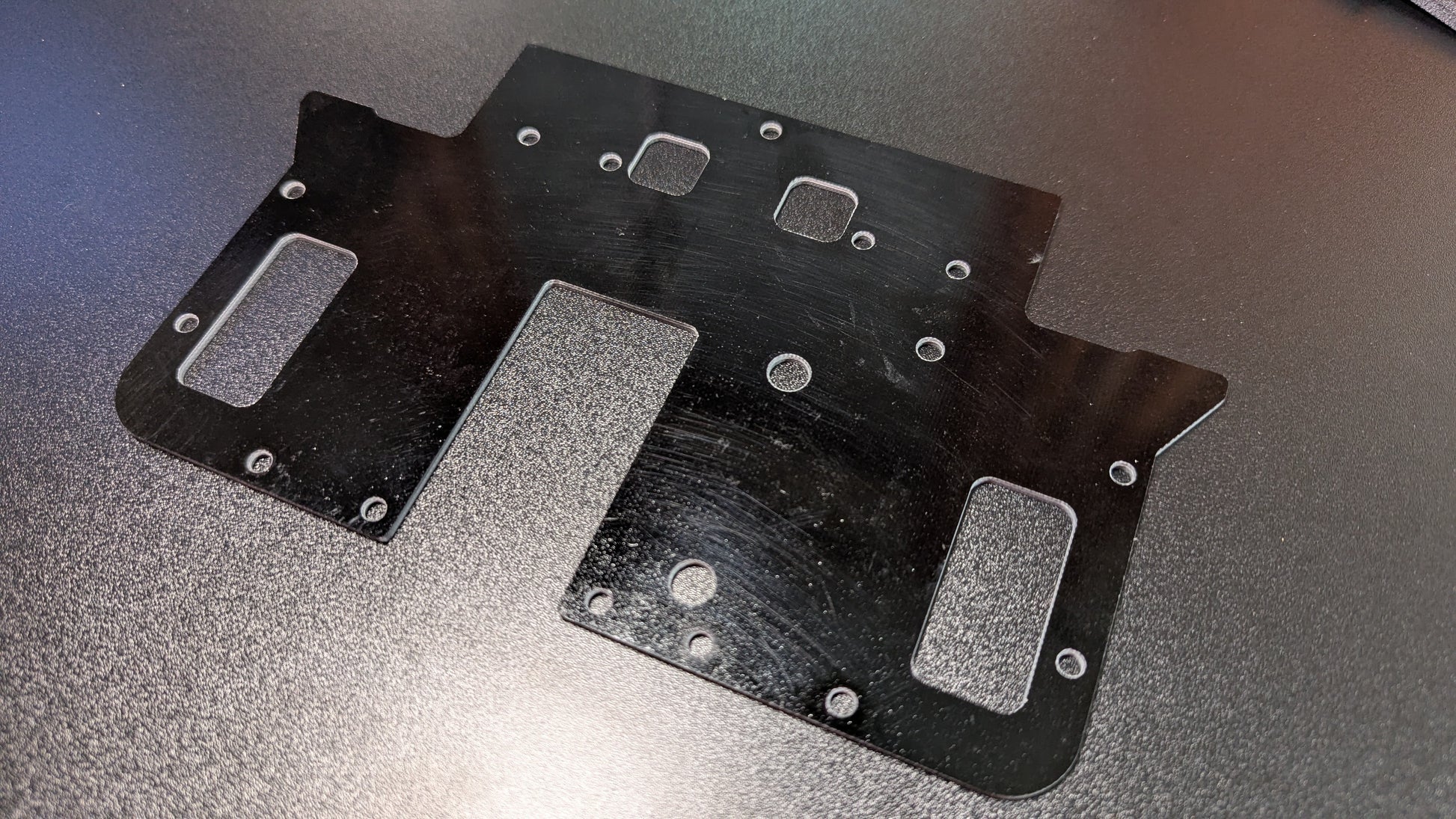

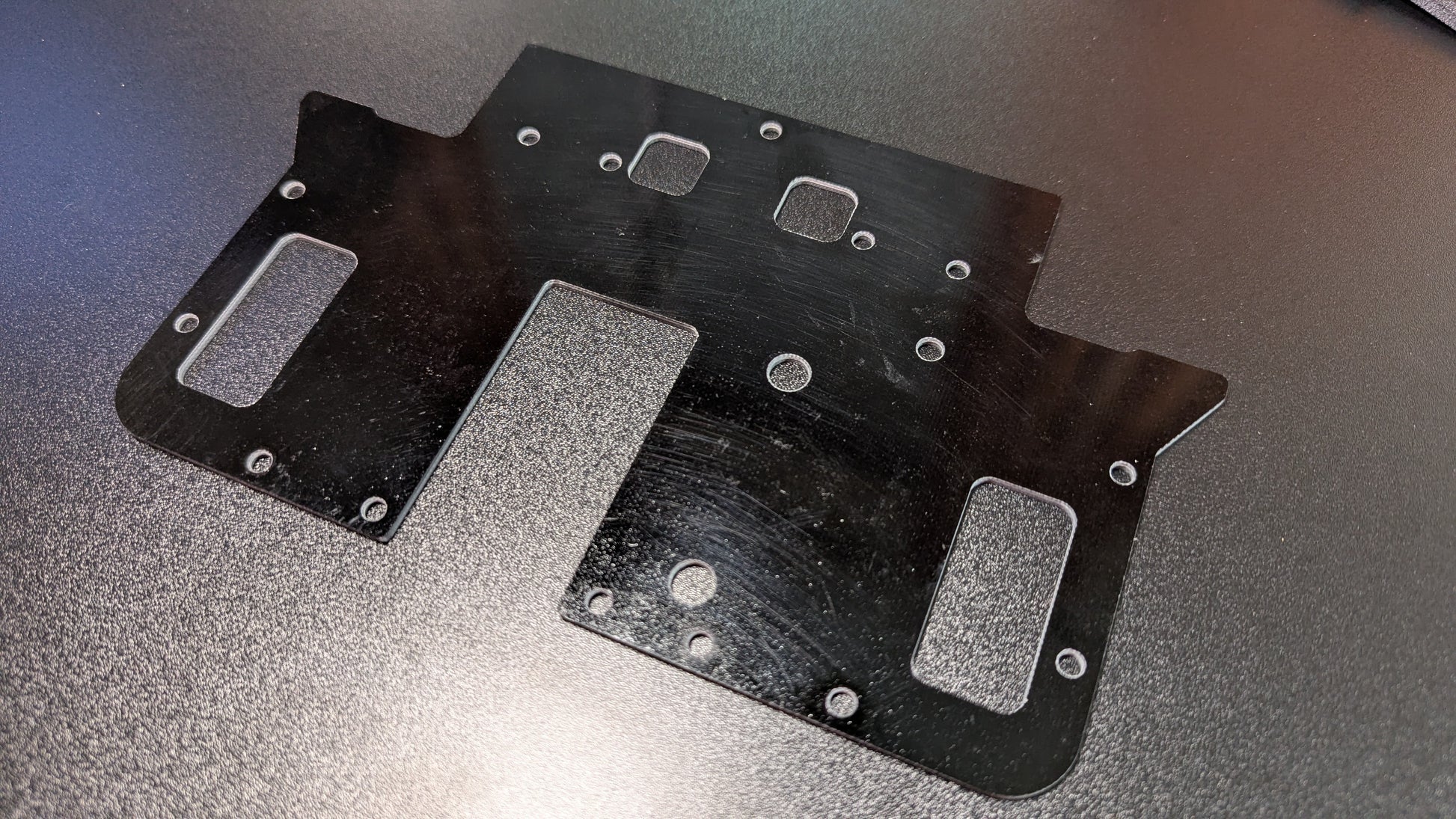

- SSP 1.0 Lid, 2.5mm Thick G10 (fiberglass composite), 96 grams each (3.39 oz)

- SSP 2.0 Lid, 2.5mm Thick G10 (fiberglass composite), 96 grams each (3.39 oz)

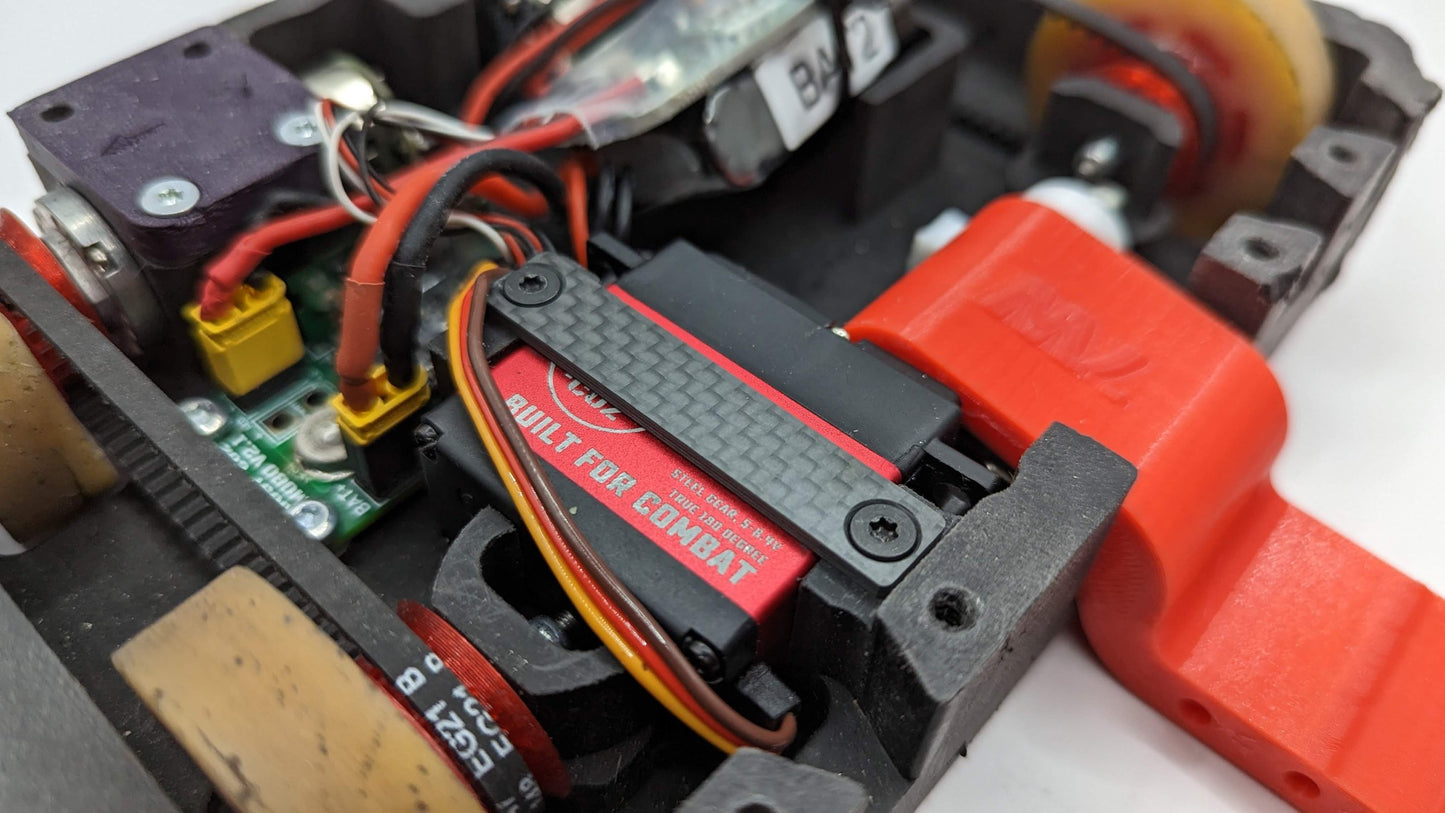

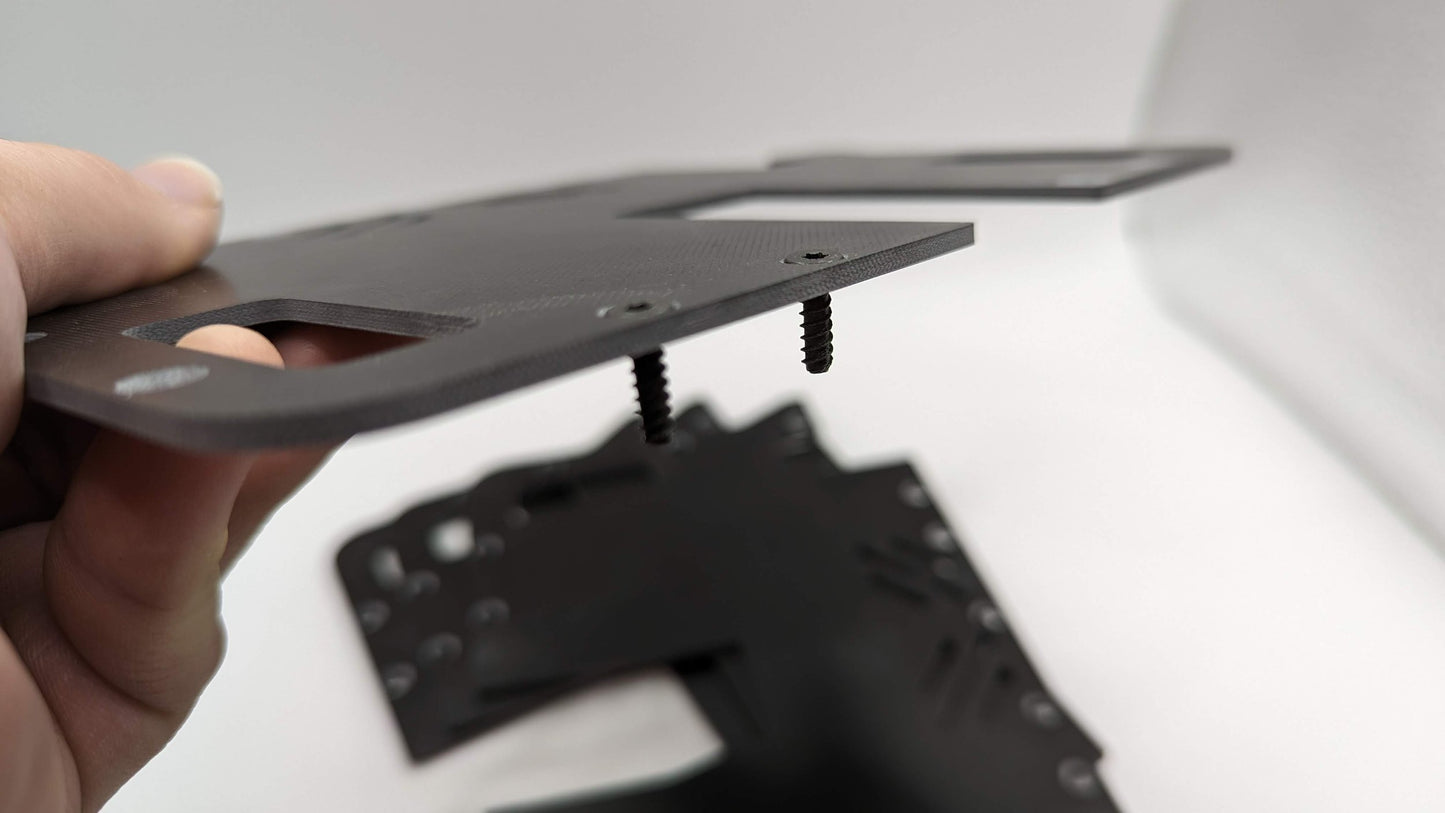

- Servo Retainer, 2mm Thick Carbon Fiber, 1.6g each (0.07 oz)

- SSP Chassis V1.3 - Billet Machined UHMW 211g each (7.44 oz)

- SSP 2.0 Titanium Lid, 0.050" thick, may be 0.063" based on material availability

- SSP 2.0 Chassis - Billet Machined UHMW (coming soon)

Note, thickness may vary slightly by batch and weights are approximate.

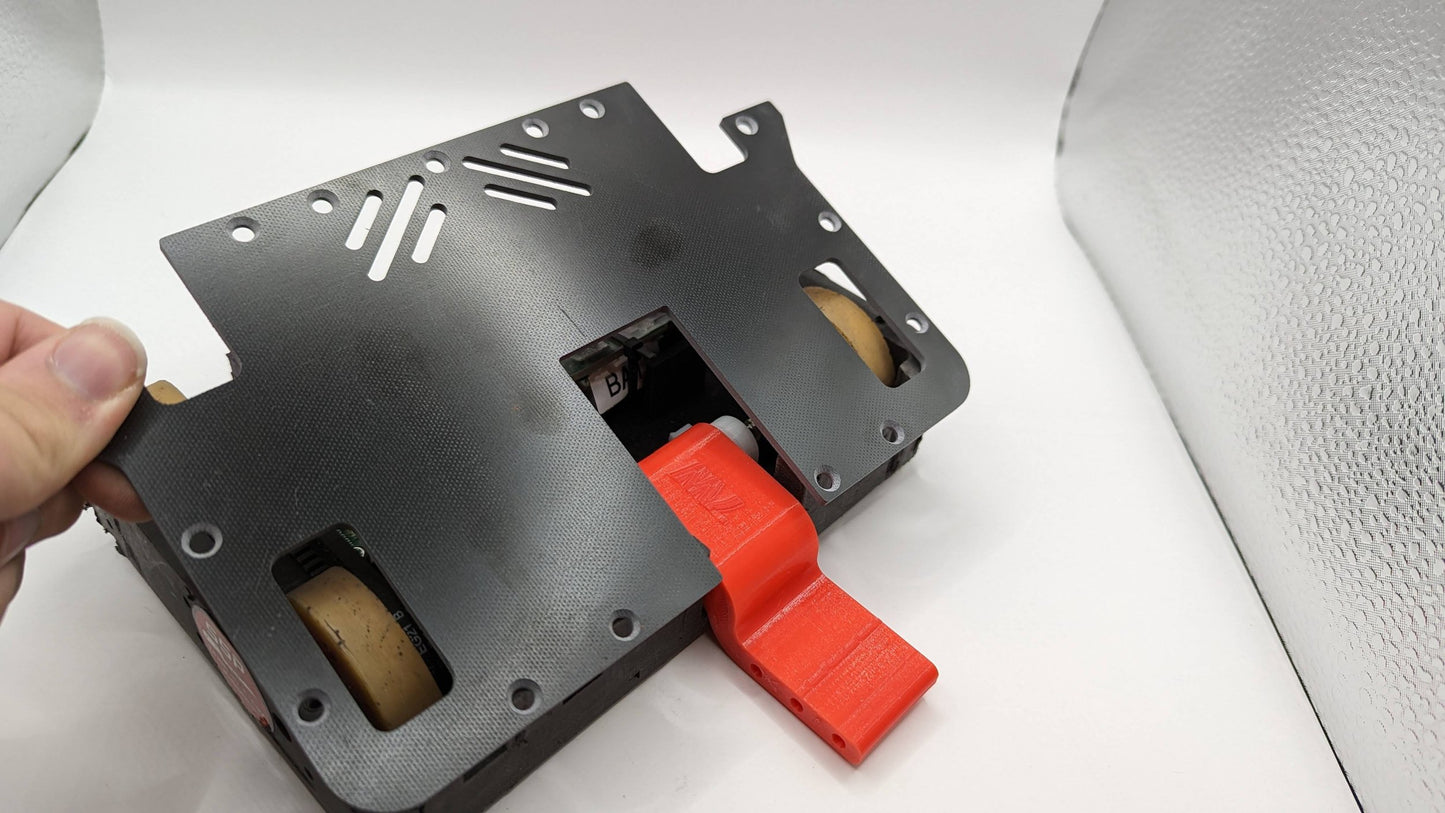

Shameless Self Promotion’s chassis after Jan and March NHRL 2023

Composite parts may fray or delaminate if they take hits on the edge and can create jagged sharp edges. Please handle damaged lids carefully.

Note: As of November 2023 all replacement SSP Chassis shipped should now be the new V1.3 design. This version was changed to add extra holes for possible future attachments, reinforce weaker areas, and expand the battery compartment 1/8" or 3mm longer, plus a few other minor improvements. It is 10 grams lighter than the prior versions. Everything for the robot is cross-compatible with all chassis versions, except for the lifter lock which needs an extra cutout.

Q&A

Can I use my SSP 1.0 parts in an SSP 2.0 chassis?

Generally yes! The SSP 2.0 chassis requires a different lid and a 3D printed insert to support the DartBox drive motors, but the 1.0 urethane wheels, belts, steel forks/wedges, and electronics will all fit a 2.0 chassis. The TPU fork and wedge mounts for 1.0 should squeeze into a 2.0 chassis but these were also redesigned. The lifter arms remain unmodified from 1.0 to 2.0. You will need to buy #6 plastite pan head screws for the 2.0 chassis as well.

How often do these parts need replacement?

Lifetimes of components will vary based on what bots you end up fighting and the sort of damage they can dish out. However, you should not be expecting to replace any of these after every fight! Just two SSP chassis were used by Seth for the January and March NHRL events and despite taking a beating, both are still perfectly usable after 13 combined fights against some of NHRL’s best beetles. G10 lids tend to get damaged the most against vertical spinners which can bite into the chassis and uppercut the edges of the lid, and overhead attack bots obviously pose a serious danger as well.

For CAD models of these components, take a look at the full robot SSP CAD model!

You may be wondering, why is the chassis so expensive? There are several reasons:

- Material cost. Only high-quality virgin material is used, none of the cheap reprocessed stuff, and only genuine UHMW rather than weaker HDPE can be used. Just a single 12 x 12 x 1.25” slab can cost over $120 here in the US.

- Machining is very labor intensive. Even though a CNC machine does all the cutting, material needs to be loaded by hand, the toolpaths are programmed by skilled machinists, etc. A complex part like this with machining on 4 sides gets expensive fast.

- UHMW is hard to work with. It’s extremely slippery making it hard to clamp in place, and when machining it can heat up and warp easily, so extra care must be taken and it cannot be machined too fast or it may even melt.

Due to all these factors, almost no machine shops would make a single chassis for less than $150 - it’s only by buying batches of 25 or more that the SSP Kit can be made affordable.

G10 Lid arrived safely with no cracks in material from shipping and handling. Counter sunk holes were well done. No edge fraying or delamination was noted. After taking some direct hits the G10 material began delaminating and the wings near the back of the lid eventually broke off. One or two of the screw holes on the sides broke through as the cross-section is thin but nothing a washer couldn't fix. The damage to the lid was expected due to mechanical properties of material but was and is still functional. I have already ordered a replacement.

The UHMW billet chassis fit all electrical and mechanical components nice and snug even with some different parts than what the S.S.P. kit was designed with. After taking direct side and rear hits from egg beater and horizontal bar spinners the chassis is still in operational condition. Overall build and manufacturing quality of the lid and chassis are as expected. One thing to note is the lid and chassis mounting holes were a little misaligned but once all fasteners were in position and tightened there were no issues.